Abraham Anapolsky, one of the metallurgical collaborators that vetted the steel chapter in my book volunteered to shoot some scanning electron microscope (SEM) images of blades that Konrad Sauer sharpened with his 15,000-grit Shapton waterstone and his ultra-fine natural Japanese waterstone. If you haven’t read the first part of this story go here to get up to speed or what follows won’t make much sense.

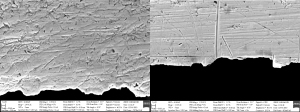

Abraham writes: “I finished the data collection, and I have a few ideas I am working on especially about what makes a hard sharp edge (based on some analysis of the edge composition), but I am not finished thinking about everything. However, I do have an answer as to why the two blades look different. If you notice, in the images of the blade honed with the natural waterstone, the surface looks like crumpled paper, the higher mag picture shows this is due to random short scratches. The Shapton images on the other hand have large areas that are smooth and the scratches are all of a specific orientation. Both samples show a range of large scratches (~0.25um wide) that are continuous and very visible; I imagine that these are the remnants of the original grinding, or you used the same coarse stone on both of them. The random short scratches are consistent with a surface moving over an abrasive that is free to move (i.e. a slurry) whereas the specific direction scratches are consistent with a surface moving over a fixed abrasive. Note also that the edge on the natural-stone images has regular fine rounded serrations, whereas the Shapton edge shows no regular serration, but kind of random straight sections. Also, the Shapton edge is much thinner than the natural waterstone edge.”

Double-click on the images to see them larger.

The earlier entry suggested that the softer abrasive of the waterstone was selectively removing the softer steel around the carbides more readily than the carbides themselves, creating the matte surface. This new input suggests that the loose nature of the waterstone’s slurry is (also) contributing to the random, matte surface quality. The Shapton’s grit grains are better anchored in the stone surface which allows them to shear a straight groove in the steel, carbides and all, thus creating the flatter surface.

Mystery solved? I think so. Let me know what you think.

By the way, in Konrad’s defense I need to repeat something from my book (page 213):

I recently mentioned to Chris Schwarz, editor of Popular Woodworking Magazine, something about using a simple, USB, toy microscope to look at edges before and after sharpening. His reply was, “I got to play with one of those gizmos and it was very… humbling.” I know what he means. Magnifying a sharpened edge can spotlight a dismaying array of results. Even an edge that you are certain is as sharp as any living being could make it, one that passes all the sharpness tests and performs beautifully, will show scratches, nicks and abject irregularities that you’d swear couldn’t possibly be there. It’s not for the insecure. If Chris’s experience with the toy microscope was… humbling, mine with the SEM was undoubtedly… more so.

So, don’t worry Konrad. Those edges you sharpened may look nasty at 3000x but I, for one, know how sharp they really are.

My thanks to Konrad for asking the interesting question and providing the samples for the SEM, and to Harrelson, Gary and Abraham for offering interesting answers.

Ron,

That’s it – I quit! I *thought* I had learned to sharpen the irons on my planes, and now this… I really don’t want to have to buy one of those microscopes. Maybe I will have a chat with Sandy at dinner, tonight.

Thanks for the truly enlightening photos, to everyone involved. “Terrific” does not even begin to tell the story.

Al

I have a 10x to 60x stereoscope. It’s a very useful tool when working with edged metals. If you keep in mind you operating under magnification, there’s no need to be humbled.

Ron,

Thanks for the revealing images. Your interpretations make sense to me. So, the more randomly oriented and variable depth scratch pattern produced by the natural stone and its slurry diffuses the relected light which we see as a “matte” surface.

A few observations/questions:

Near the very thin edge produced by the Shapton, there appears to be fractures, or impending fractures, in the steel. I wonder if these would be prone to shearing in use and thus create chips in the edge. Has the Shapton pushed (exceeded?) the edge-holding capabilities of the steel? Has the edge been work hardened by a burnishing effect?

There appears to be more ridges more than scratches in the Shapton-sharpened steel. Is this an optical illusion? If not, how do you suppose they got there?

The natural stone seems to produce more variability in the depth of scratches than would seem explained by retained scratches from grinding. Perhpas the grit in the slurry is free to be variably crushed into different size particles which produce the many different depths of scratches.

Well, I guess this all begs the question: which of the blades would we like to work with? I’m a Shapton user but the blade from the natural stone looks like it might hold its edge longer.

Great stuff, Ron, keep it coming, and thanks again.

Rob Porcaro

Excellent photography and analysis by the metallurgist. Great blog entry.

The natural stone appears to have created a more compact and consolidated front edge than the Shapton. I am speaking of the “…regular and fine rounded serrations..” noted by the metallurgist, as well as his observation that the Shapton edge is “thinner”. This suggests to me that the natural stone has created a more robust and durable edge, where the Shapton looks like it would be more fragile once it hits the wood. It would be interesting to see what happens to these blades after each one planes 50 lineal feet in a domestic hardwood, or Doug fir for that matter.

Hi,

Sharpening has been a hobby of mine for few months now, by no means am I an expert in the subject matter. I posted some pictures I took at 100x of the knife edge sharpened by different stones. Go to ws.magicmrv.com and click on the link at the top to see pictures. email me at igorpetrusky@hotmail.com if interested to carry on this discussion. Something to consider in natural vs synthetic debate is the shape of the abrasive particles, not just the size. All synthetic stones use crushed abrasive, which has sharp edges, so it scratches the metal. Natural stones are more round, hence they compress the metal, microscopically cold-hardening it. This is also inline with the V shaped vs U shaped scratches. The light reflected from the smooth walls of V scratches will interfere and overall result will be same as from 2 parallel mirrors. In the case of U shaped scratches, there is allot less parallel surfaces, so we do not see as bright of the reflection.

I suspect that fixed grit will often wear down to a mesa type profile. This would in turn scrape and produce a flatter profile.

Loose grit, by abrading and not scraping or pushing steel as much, would tend to reduce snag and tear causing less stress to the fine edge. Since it does not do as much scraping, less burnishing action will result. This means less burr and less smoothing by metal movement.

While the scraping action of fixed grit may produce a finer finish, grit for grit, loose grit’s reducing burr issues and stress on the edge probably more than make up for this.

Bob

After reading your blog on matte surface mystery topic.I enjoyed reading you post. I am sharing it with my other friends as the information is really very useful. Keep sharing your excellent work.

I just discovered your blog today (Aug ’13). Thank you! I note that in Matte Finish 1&2 you have successfully and tantalizing avoided the key question: which edge does Konrad prefer? The shapton, or the Jnat?

I asked Konrad what he’s using for final honing: “I am still doing final honing on my 15k Shapton Pro series stone.”

I’m sorry but I can not English – I use the compiler.

I admire your beautiful pictures of the microscope.

Sharpen razors lot of years and I use gemstones Shapton 12K and 30K and also various other stones such as Charnley forest sharpening stone . I have a microscope that can 200 magnification. Here are pictures of my sanding. All are at the same magnification .

http://forum.britva.cz/viewtopic.php?f=6&t=1157&p=17757&hilit=laick%C3%A9+nabrou%C5%A1en%C3%AD#p17757

If the photos do not appear , please register .

I was intrigued by your photos from the microscope to look surface and the leading edge of the blade. In my grinding is necessary to be absolutely straight edge blade . This is because I’m doing grind perpendicular to the blade . Feel grinding lengthwise edge to edge, and therefore the material rips off and cracks are seen . It would be good to do the same photos from sanding perpendicular to the edge of the blade. Anyway fully accepted that the microscope is a blessing and a curse in one device . I could not see without a microscope to grind as a microscope to see how I need to continue to improve .

I wish you still a good blade and health, Petr , Czech Republic .

If you ever have the chance to do more work on this, it would be interesting to see micrographs after the blade has been used. The idea is to see whether edges from natural vs. man-made stones differ in durability and differ in how they degrade. It would be interesting to see micrographs after even a single shaving, then after 2, 10 and 100 shavings.